Within the early days of the trendy Olympics and Paralympics, athletes competed utilizing heavy, non-aerodynamic gear. The document for throwing a javelin, as an example, has nearly doubled since 1908, when the game was launched.

Athletes have gotten higher – however so has their gear.

In reality, sporting gear (and the supplies it’s created from) has improved in nearly each sport. Fibre-reinforced plastics, particularly, have been revolutionary. These composite supplies generally mix plastics with sturdy carbon or glass fibre. Now you can discover them in most sports activities performed at excessive stage.

These sturdy, bendable and light-weight supplies have made it doable for athletes to push the bounds of their sports activities, win medals and produce delight to their nations. However they arrive with a hidden value.

Composite supplies are notoriously exhausting to recycle. And the quantity of waste from sports activities is rising quick. Our analysis affords a manner to cut back this waste – and extract precious carbon fibres.

Composites in every single place

Fibre-reinforced polymers have turn into ubiquitous due to their distinctive properties. They provide a mix of low weight, flexibility, energy and sturdiness. The properties might be modified by adjusting fibres, mixing supplies and altering how sporting gear is designed.

For those who choose up a contemporary tennis racket in a single hand and an previous picket racket within the different, you’ll discover the distinction. New composite rackets are gentle and powerful, letting gamers obtain sooner swing speeds.

Badminton rackets, too, have left strong wooden behind. As we speak, even shuttlecocks have feathers strengthened with carbon rods.

Operating footwear depends on carbon composites to spice up springiness, assist propulsion, enhance heel stability and scale back foot fatigue.

Biking has enormously benefited from carbon composites. Trendy racing bikes are sometimes made completely of carbon fibre, together with lugs, tubes and connections. These bikes are light-weight, extremely sturdy and with considerably decrease air resistance in comparison with their metallic counterparts.

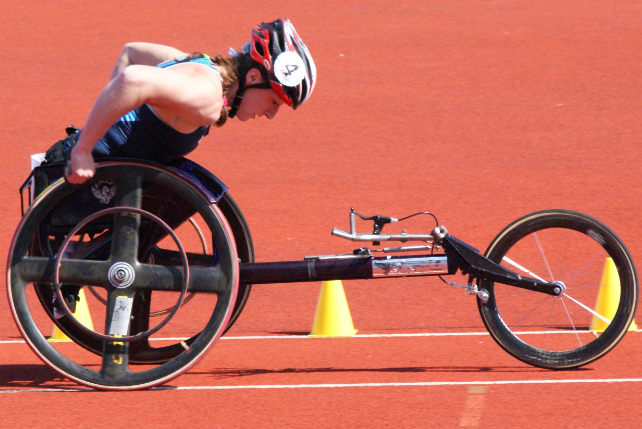

Wherever you look, you see fibre-reinforced plastic composites. The bows in archery, the poles in pole vaulting, the wheelchairs within the Paralympics, the carbon web poles in volleyball, the saddles, horseshoes and helmets in equestrian disciplines, the gun bipods in capturing, the golf membership shafts in golf, the boats in crusing, the skateboards in skating, the surfboards in browsing and even the climbing partitions in mountaineering – all are actually fabricated from composites.

When the video games are over

These supplies have remodeled many sports activities. However composites are fabricated from a number of supplies mixed. Which means they’re typically exhausting to recycle.

In the UK, as an example, about 90 % of all composite waste goes to landfill. Solely 2 % is reused for carbon fibre. Producing new composites consumes a lot of power.

Globally, about 7,000 tonnes of composite sporting gear reaches its finish of life and may very well be recycled yearly. Demand for recycling is growing. This stream of waste now accounts for nearly 9 % of the overall composite market.

As these composites have turn into ever extra common, researchers have appeared for higher methods to recycle them – ideally, in methods that are additionally worthwhile. Whereas many strategies are usually not worthwhile, our earlier cost-benefit analysis discovered a number of strategies which present promise.

In our latest analysis, we put one methodology to the take a look at: thermochemical recycling.

Contemplate the problem of recycling composites. They’re typically coated with polymers or resins to make their surfaces extra sturdy. However this makes more durable to tug these supplies aside. Carbon fibres are essentially the most precious half in these composites.

To seek out methods of extracting these fibres, we took damaged bikes fabricated from carbon fibre composite and experimented with recycling utilizing chemical substances and warmth.

By means of trial and error, we developed extremely environment friendly chemical strategies of pre-treating damaged bikes and found the optimum temperature to soften them: 425°C.

At this temperature, we may extract these fibres comparatively intact. The recycled fibres retained 94 % of their unique stiffness and 90 % of their unique energy.

This implies they are often put to completely different makes use of, the place barely decrease energy and stiffness are acceptable.

Recovered carbon fibres can be utilized in 3D printing of different bike elements, providing a excessive weight-to-strength ratio and elevated sturdiness, and even in strengthened concrete.

The place to from right here?

It’s exhausting to see athletes ever shifting again to the heavy, non-aerodynamic gear of the previous. But when precious supplies might be recovered cost-effectively from sporting gear on the finish of its life, it creates an incentive to do one thing helpful with this rising waste stream.

Whereas our new methodology makes use of much less power than present warmth recycling processes and produces comparatively environmentally pleasant waste by-products, we imagine we will enhance this course of additional so it makes use of nonetheless much less power.

Finally, we hope this methodology will likely be helpful to assist small and medium recycling companies course of extra composite merchandise from sports activities.![]()

Ali Hadigheh, Senior Lecturer, Structural Engineering, College of Sydney and Yaning Wei, Postdoctoral Researcher, Civil Engineering, College of Sydney

This text is republished from The Dialog beneath a Inventive Commons license. Learn the unique article.